Distribution is often referred to as the “Achilles heel” of the cold chain operation and has a major impact on society. According to a study (pdf) released by the UN Food and Agriculture Organization (FAO) in 2011, approximately 1.3bn tonnes (or one-third of the world’sfood produced for human consumption) is lost or wasted globally due to inefficiencies in the cold chain. Inconsistent and improper refrigeration through the use of reefer containers is a large contributor to this waste

REEFER MONITORING

At its most basic form, is done manually. Technicians walk around a port or vessel looking at the operating temperature of each container (many times totaling hundreds/thousands of containers), making sure that the refrigeration equipment is functioning properly. The technicians completing these checks then record the information (manually), and later enter it into a system (manually) that generates reports for customer and billing purposes. The cargo inside reefer containers is typically of high value and whoever is transporting or storing the container is responsible for that cargo. Simply put, reefer monitoring is a MUST.

Manual reefer container checks typically occur every 6-8 hours. In the event of a critical failure in the cooling equipment, cargo could be completely lost before anyone is aware that there was even a problem. Although still widely used throughout the industry, you can see that manual reefer monitoring is both inefficient and unreliable. Luckily, knowing exactly what every member of your graduating class is doing isn’t the only information that is available at your fingertips these days.

As the need for and use of Reefer Monitoring Systems continuously increases so will the reliability and efficiency of the cold chain and other refrigerated distributions.

GAME CHANGERS

In the mid 1980’s Refrigerated Transport Electronics, Inc. began the development of an automated remote reefer monitoring system using technology known as Power Cable Transmission (PCT). The system is both extremely simple to install and use.

Communication takes place over the existing power cables between each reefer container’s PCT slave modem and RTE’s master modem. By simply plugging the reefer’s power cable into a reefer outlet, such as those manufactured by ESL Power Systems, communication is established.

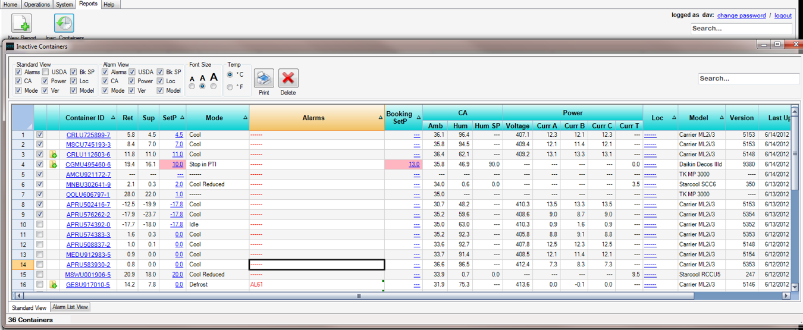

The PCT equipment in conjunction with RTE’s (GRASP™) (pdf) software has the ability to receive and control container operation parameters such as:

- Pre-Trip Inspections

- Temperature and Alarms

- Set point changes

- Initiate defrost

- Ability to integrate with the Terminal Operating System (TOS) to exchange monitoring data

FAST FORWARD

As cargo becomes more valuable and the intermodal industry more competitive, real-time information of one’s refrigerated materials needs to be available. With the help of the information age and increased use of reefer monitoring systems, RTE’s technology is evolving to meet the new standards.

Today, RTE’s Networked Remote Reefer Communication Engine with Tethering (NRRCE-T™) (pdf) and Wireless Reefer Acquisition Device (WRAD™) (pdf) offer real-time monitoring via the external data port on each reefer container. This makes it possible to monitor 100% of the reefer containers.

In addition to the capabilities of PCT (listed above), NRRCE-T and WRAD:

- Communicate directly with the reefer controller (A PCT slave modem is no longer required)

- Allow for multiple transition methods (Zig bee, GSM, Satellite, Wi-Fi)

- Faster updates with NRRCE-T, each reefer’s status is updated every minute

Land Distribution

Once reefer containers reach the correct port, they will likely need to be transported via truck/trailer or rail methods to their final destination.

- By using RTE’s interface module RRCE-B together with 3rd party cellular (GSM) and/or satellite communication with RTE’s Global Remote Communication Device, it is now possible to monitor and control reefer containers traveling by land as well.

As the need for and use of Reefer Monitoring Systems continuously increases so will the reliability and efficiency of the cold chain and other refrigerated distributions. RTE makes the process of locating your reefer containers and ensuring they are operating properly as simple and convenient as logging into check your webmail, thereby easing the ability to ensure the integrity of one’s cargo.