This year, a Secret Santa Gift Exchange throws the ESL team into a holiday frenzy. Watch the trailer for what critics are calling “Electrifying” and “The best movie never made”. Our 2016 holiday video is sure to please audiences of all ages!

The Official Blog of ESL Power Systems, Inc.

This year, a Secret Santa Gift Exchange throws the ESL team into a holiday frenzy. Watch the trailer for what critics are calling “Electrifying” and “The best movie never made”. Our 2016 holiday video is sure to please audiences of all ages!

Founded in 2003, The Spirit of the Entrepreneur Award recognizes the Inland Empire’s top entrepreneurial business leaders and was designed to recognize these leaders’ accomplishments and celebrate their success stories. The Spirit of the Entrepreneur Award has honored more than 200 finalists and bestowed the award to 70 entrepreneurs since its inception. According to Corona Business News, The Spirit’s black tie awards ceremony is becoming known as the top business event in the Inland Empire bosting approximately 800 attendees for this year’s event on November 15th at the Riverside Convention Center.

This year, ESL’s President Michael Hellmers is honored to be amongst the Inland Empire’s elite as one of the (5) Corona based finalists. For a successful nomination candidates must have demonstrated innovation, leadership, performance, character, entrepreneurial mindset and vision. According to IECE, the Spirit of the Entrepreneur recipient must be an individual who truly possesses the entrepreneurial mindset and is constantly pushing to improve their businesses, always striving to advance their ventures and facilitate progress in the industries in which they work.

As a two-time finalist, Michael Hellmers and ESL feel privileged to be nominated amongst such great entrepreneurs. As our company strives to reach new levels of success and aims to contribute to the betterment of the community, we take great pride in being recognized with such a diverse and remarkable group of entrepreneurs.

In February, at the beginning of our adventure, we described what Lean Six Sigma is, and the need for implementation at ESL Power Systems. ESL constantly seeks to identify ways to improve. To recap, even the best companies have waste (things that don’t add value to the product) and variation in processes that cost a company money. Our goal is to focus on getting the customer what they want, when they want it, “right the first time.”

In February, at the beginning of our adventure, we described what Lean Six Sigma is, and the need for implementation at ESL Power Systems. ESL constantly seeks to identify ways to improve. To recap, even the best companies have waste (things that don’t add value to the product) and variation in processes that cost a company money. Our goal is to focus on getting the customer what they want, when they want it, “right the first time.”

OUR ROAD MAP

The first step in our journey was to educate and help everyone on board understand the path we were heading down. This very important first step allowed employees, from company owners to shop assemblers, comprehend the concept of continuous improvement and got everyone moving in the same direction.

TOOLS ALONG THE WAY

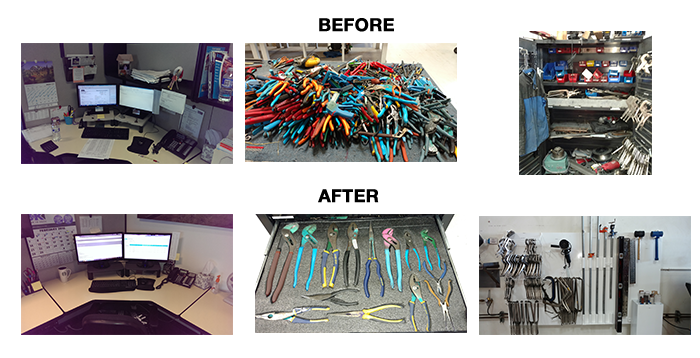

The first tool we put in place was 5S. The goal of 5S is to organize the workplace for efficiency and effectiveness by identifying and storing the items used, maintaining the area and items, and sustaining the new order. The 5S steps are Sort, Set-in-Order, Shine, Standardize and Sustain. At ESL, I’m happy to say that we are well along the 5S road!

Another tool being used is the “value stream map.” This “map” helps navigate our processes and seeks to eliminate waste. Along the same lines, we have implemented software called LeanKit, which assists in visualizing our work as it flows through our company, providing a big-picture understanding of our procedures.

NAVIGATIONAL PLANS

Moving forward, ESL’s executive committee has completed what we call the “3SL.” This is a 3 year plan for the organization that spells out a clear “true north;” ensuring everyone in the company knows what our plans are for the future. This transparency of goals ensures the company as a whole is heading in the right direction. The 3SL contains (3) elements:

This has become the most important document in the company.

We have made much progress over the last several months, and we must work hard to continually improve our products and processes to remain competitive in an ever changing market. We feel positive we will be successful and through our continuous improvement program create additional value for our customers in the future.

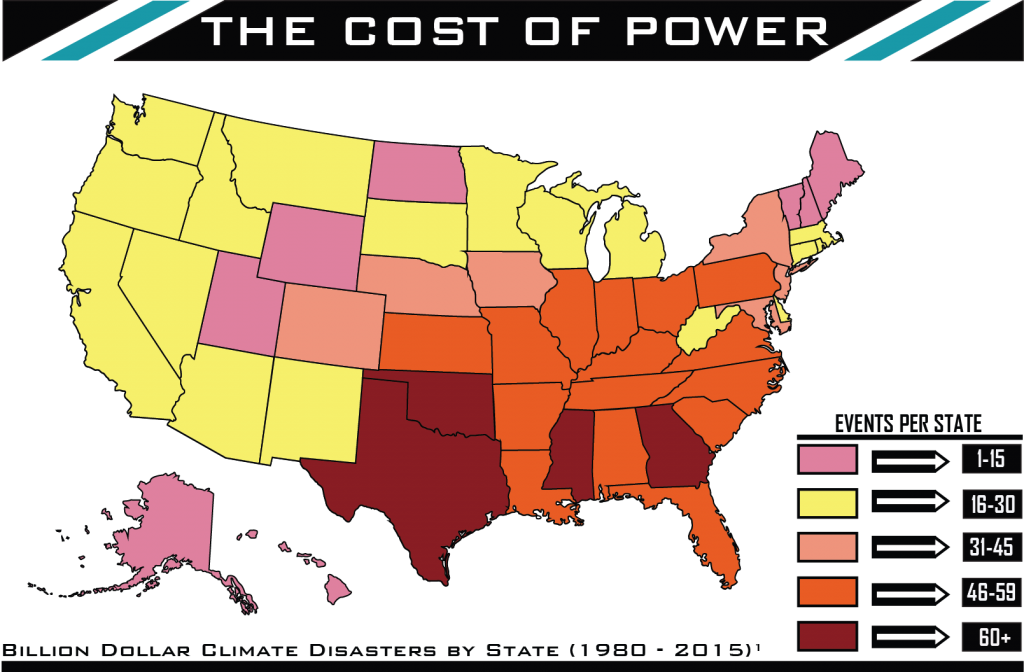

The reliability of power over the past 15 years has been strained by increased demand by growing populations, aging infrastructure and more frequent occurrences of extreme weather. As seen in bar graph [a] on the right, the number of weather-related power outages has doubled every five years since 2000. Although the timing of when these outages happen fluctuates from day to day, season to season, and year to year, the data shows that weather-related power outages are steadily on the rise.

The estimated costs of weather-related power outages, by year, are provided in graph [b]. The variations in cost change considerably year to year. These cost estimates are dominated by the impact of large storms and the numerous costs associated with power outages. These costs include lost output and wages, spoiled inventory, inconvenience and the cost of restarting industrial operations. Although weather is a major factor in the cost of power, the costs associated with power outages are influenced by the amount of time that the power is out as well. The pie chart [c] shows the average length of reported power outages in the digital economy, continuous process manufacturing and fabrication/essential services sectors of the economy. Regardless of what industry your business is in, the longer the power is out the more money you are losing.

As the climate changes and infrastructure ages, the economic and social impacts of power outages may be unavoidable. However, the effects can be mitigated by being diligent and taking appropriate steps to minimize operational downtime. ESL’s emergency power connection equipment is very cost-effective, especially when compared to the cost of being without power for extended periods of time. In addition, our emergency power products provide users with safe and simple operation so that grid-tied facilities can quickly connect to portable power when it matters most.

For more information on how ESL can help you be prepared for the next major power outage, contact us.

Sources:

1-Billion-Dollar Weather and Climate Disasters

2-Power Outages On The Rise Across The U.S.

3-Economic Benefits of Increasing Electric Grid Resilience to Weather Related Outages

4-The Cost of Power Disturbances to Industrial & Digital Economy Companies

On April 21st ESL celebrated our 25th Anniversary with customers, vendors, friends and family at our facility in Corona, CA. The highlight of the night was catching up with the many individuals whom have helped us get to where we are today.

Founded in 1991, ESL began as a custom control panel business located in Yorba Linda, CA with just 4 part-time assemblers. In 1995, ESL Power Systems, Inc. emerged as a manufacturer of safety-interlocked reefer outlets, and soon began to develop cord-connected electrical power equipment for a wide variety of industrial and commercial applications. Thirteen years after founding, the ESL Family of Companies moved 8 miles east to our current facility in Corona, CA. After 25 exciting years, ESL Power Systems, Inc. now operates once again as a single company and has over 130 employees. We are one of the largest manufacturers of reefer outlets worldwide supporting Intermodal Container industry and Port Terminals, and we are known as the “best-in-class” builders of Ship-to-Shore Power Mounds, Company Switches for Set Stage applications, and also for our StormSwitch and TripleSwitch product lines for back-up power solutions during grid outages. And, of course, ESL is still the premier Custom Control panel Builder in Southern California!

ESL thanks those who have contributed to our success the past 25 years and we look forward to continuing to work with you for many years to come!