In February, at the beginning of our adventure, we described what Lean Six Sigma is, and the need for implementation at ESL Power Systems. ESL constantly seeks to identify ways to improve. To recap, even the best companies have waste (things that don’t add value to the product) and variation in processes that cost a company money. Our goal is to focus on getting the customer what they want, when they want it, “right the first time.”

In February, at the beginning of our adventure, we described what Lean Six Sigma is, and the need for implementation at ESL Power Systems. ESL constantly seeks to identify ways to improve. To recap, even the best companies have waste (things that don’t add value to the product) and variation in processes that cost a company money. Our goal is to focus on getting the customer what they want, when they want it, “right the first time.”

OUR ROAD MAP

The first step in our journey was to educate and help everyone on board understand the path we were heading down. This very important first step allowed employees, from company owners to shop assemblers, comprehend the concept of continuous improvement and got everyone moving in the same direction.

TOOLS ALONG THE WAY

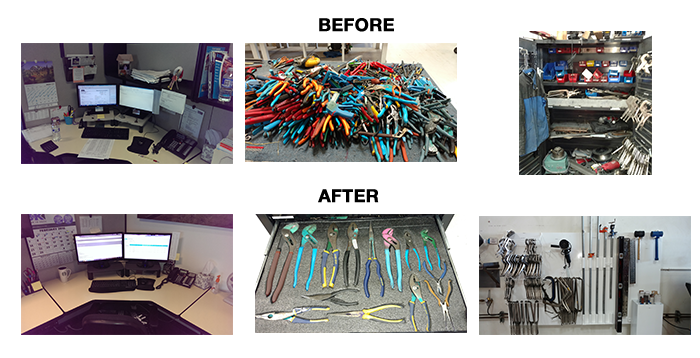

The first tool we put in place was 5S. The goal of 5S is to organize the workplace for efficiency and effectiveness by identifying and storing the items used, maintaining the area and items, and sustaining the new order. The 5S steps are Sort, Set-in-Order, Shine, Standardize and Sustain. At ESL, I’m happy to say that we are well along the 5S road!

Another tool being used is the “value stream map.” This “map” helps navigate our processes and seeks to eliminate waste. Along the same lines, we have implemented software called LeanKit, which assists in visualizing our work as it flows through our company, providing a big-picture understanding of our procedures.

NAVIGATIONAL PLANS

Moving forward, ESL’s executive committee has completed what we call the “3SL.” This is a 3 year plan for the organization that spells out a clear “true north;” ensuring everyone in the company knows what our plans are for the future. This transparency of goals ensures the company as a whole is heading in the right direction. The 3SL contains (3) elements:

- 10 key metrics tracked

- Goals for each metric

- Specific projects to get us to our goal

This has become the most important document in the company.

We have made much progress over the last several months, and we must work hard to continually improve our products and processes to remain competitive in an ever changing market. We feel positive we will be successful and through our continuous improvement program create additional value for our customers in the future.